Logistics and shipping industry is ever changing. According to Statista, the global logistics industry costs 9.3tr USD. The recent situations around the world has caused the industry to undergo rapid changes. The impact of Covid 19 pandemic is huge in the transportation and logistics industry as 90% of the population all over the world were facing travel restrictions. However, the logistics industry has adapted to these changes and is advancing rapidly with innovative technologies. This includes AI, Robotics, Blockchain, Big Data etc.. Let us see in detail these new trends in the logistics industry.

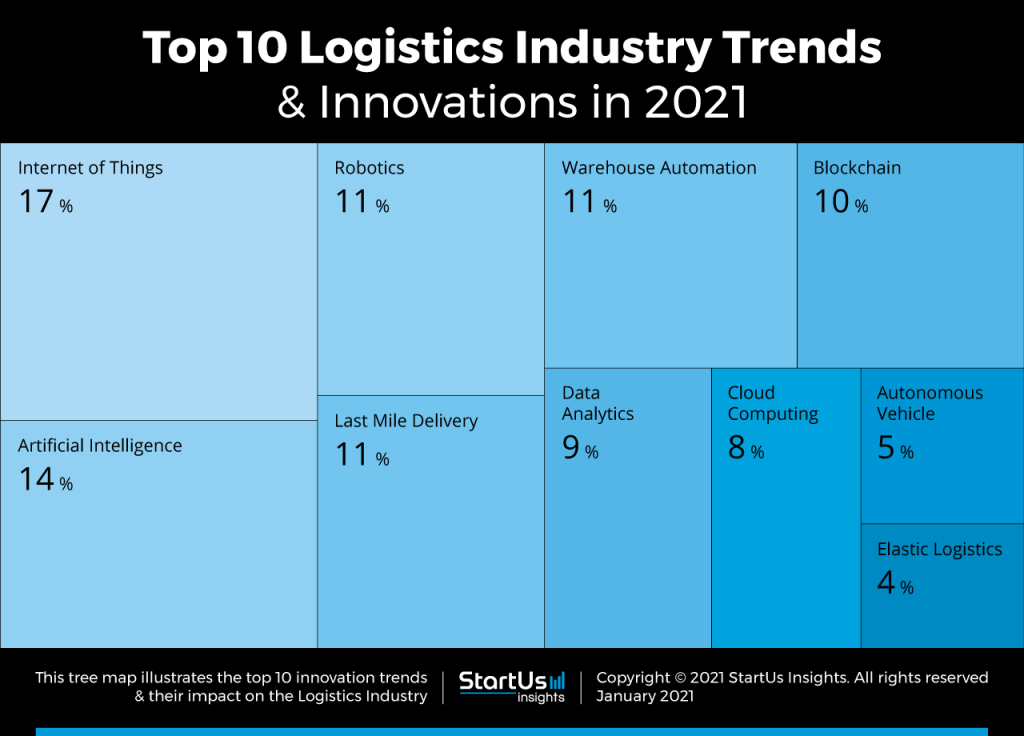

Via StartUs

1. IoT (Internet of Things)

IoT is a technology that works with the help of the Internet to connect with different peripheral devices. It helps to monitor and transfer data within these devices without any human intervention.

One of the major difficulties faced by the transportation industry is the proper tracking and management of goods. Implementing IoT technologies in logistics will help you to track the movement of shipping and make informed decisions. Also, using IoT will optimize the process of supply chain systems improving efficiency and transparency. Improved visibility of goods will help manage and track the better.

2. Big Data and A.I

Tons of data is being processed in the logistics industry on a day-to-day basis. This requires a lot of human effort and time. Integrating systems that use Big Data and AI can overcome this complexity easily. Using Big Data, logistics companies can analyze huge amounts of data at once and predict ways to optimize the logistics process.

AI has less errors and therefore higher efficiency when compared to manual operations. Also, they are time saving and can be completely automated.

3. Blockchain

Some of the primary features of the blockchain technology is its transparency, security, accuracy and ability to track. This is why block chain has an important role in the logistics industry. With the help of blockchain we can accurately track the shipments from the beginning of the process to the end.

Blockchain can improve the cost, transportation, authority and overall supply chain management.

4. Data Analytics

Nowadays, data analytics is being used in most of the industry. It has a major impact on the logistics and supply chain industry too. We are capable of analyzing huge amounts of data easily with the technologies and tools that we have today. When compared to the traditional ways of keeping data this is a big advantage.

Logistics analytics is the process of maintaining and analyzing data in the supply chain system. This data is used for different purposes such as predicting and optimizing the processes involved in the logistics. Such predictive data is further used to create reports of consumption and demand. With proper data analytics efficiency and accuracy can be improved by greater percentage.

5. Self Driving Vehicles & Drones

Logistics industry thrives on transportation of goods from one place to another. With the usage of autonomous vehicles, we can improve the efficiency in the logistics process by reducing the time, effort and money spent.

Self driving vehicles are capable of quick decision making. This will help them to take the best route possible for transportation. It will also ensure maximum utilization of vehicles and ensure fuel efficiency.

On the other hand, drones are becoming popular. Drones are currently being used to deliver parcels and other small packages to remote locations. The drone delivery system is very efficient since its fast and can be operated without human intervention.

Read more: Fundamental Factors That Influence The Ocean Freight Rates In 2021

6. Warehouse Automation & Robotics

Warehouse automation is the complete automation of the activities that happen inside a warehouse. This includes picking the packages, sorting, packaging to the final destination of the cargoes. These tasks are achieved by mini robotic machines.

Implementing warehouse automation can help minimize human interaction. However, the cost to completely automate warehouses is huge.